Dynamic Balancing Of Waste Gas Fan For Sinter Steel Plant

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace. The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the chemical properties of the ingredients. The purpose of sinter is for converting iron into steel.

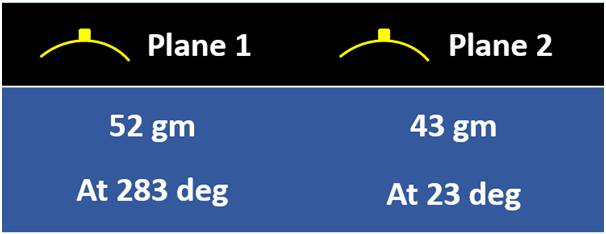

Dynamic balancing as per IS1940/1 at Grade 2.5

We have recently worked with following details

Diameter �3394 mm

Weight � 16 tons

Length � 5984 mm

Speed - 110 RPM

Scope Of Work

Fan received at our Rabale, Navi Mumbai factory.

Unloading of the impeller from vehicle.

Job lifting using 30 tons crane.

Set-up for job on machine.

Dynamic balancing process being carried out.

Balancing correction by mass adding.

Job ready for dispatch.

Process followed Dynamic Balancing work is briefed below:

Step:1

Fan received at our Rabale, Navi Mumbai factory, from one of our Clients from Steel Sector.

Step:2

Vehicle is inside our Factory for un-loading.

Step:3

Job is being lifted using 30 Tons capacity EOT crane.

Step:4

Job is being placed on our Dynamic Balancing Machine, carefully.

Initial un-balance level is checked, after setting-up CAB Instrument which is connected with the Dynamic Balancing Machine.

Step:5

Dynamic balancing process being carried out on SCHENCK Machine.

Step:6

Balancing correction is being done by mass adding

Post balancing, final un-balance level achieved, is shown on cab instrument.

Step:7

After Dynamic Balancing, the Job is kept ready for dispatch

Case Study

Relevant Services

Dynamic Balancing

Dynamic balancing is a way of balancing machines by rotating parts quickly and measuring the imbalance. The imbalance measured can then be corrected

Rotor Repairs

Remote Vibration and Condition Monitoring it is the process of monitoring a parameter of condition in machinery (vibration, temperature, speed, current etc.)